WHAT IS ISIOX®?

ISIOX ® is an innovative technology for the management of gases dissolved in wine, born within the Freewine ® project in an overall framework of economic, environmental and social sustainability.

From today available for rental .

THE MAIN PRACTICAL APPLICATIONS OF ISIOX®

Remove oxygen during decanting, when discharging road tanks, after tartaric stabilization or filtration (even pre-bottling) to improve the shelf life of wines. The dissolved oxygen reduction performance can reach -97% of the initial content, depending on the flow rate and temperature.

Remove, maintain or add CO 2 up to over 12 g/l (up to 6 bar) to modify the taste impact according to customer preferences or typical market tastes.

(- CO 2 = + softness; + CO 2 = + liveliness).

Remove hydrogen sulfide and methyl mercaptan (even when present below the perception threshold) to prevent reduction phenomena and have better olfactory cleansing.

Adjust the CO 2 pressure of semi-sparkling and sparkling wines up to 6 bar to have uniform data from the first to the last bottle and avoid bottles exploding.

Remove CO 2 before packaging in flexible containers (BiB and Tetra Pack) to avoid deformation.

Each of the functions listed occurs by avoiding stripping phenomena with loss of aromas, thanks to the use of special molecular sieves for foods (FDA certified), selective for low molecular weight gases.

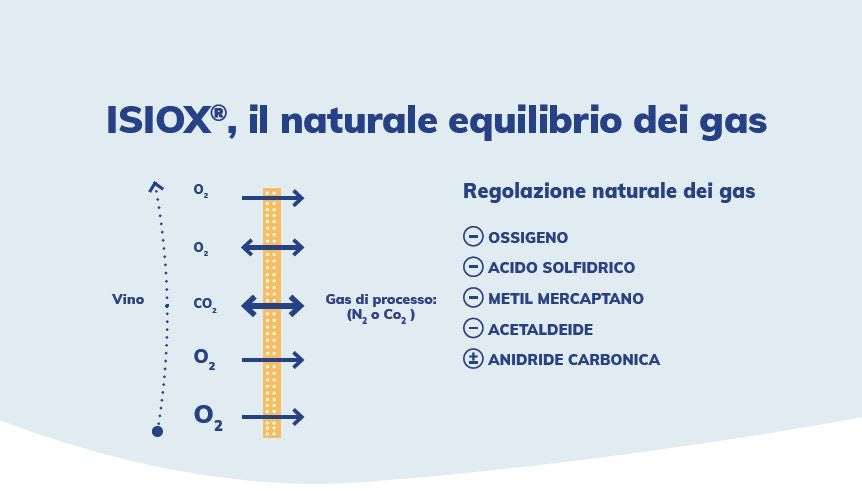

SYSTEM FUNCTIONALITY

The ISIOX ® system allows the optimization of different low molecular weight gases dissolved in wine, with applications capable of modifying the content of oxygen, carbon dioxide, hydrogen sulphide and methyl mercaptan.

ISIOX was designed according to the logic of mobility and miniaturization, in order to easily insert it into any existing process.

ISIOX is able to work up to 6 bars of pressure, also treating sparkling wines.

The use of the ISIOX ® system in a passing wine flow, both in pumping over and in line, allows the concentrations of these gases to be regulated, keeping the structure and aromas of the wine unaltered, thanks to the use of special hydrophobic molecular sieves food compliant with the ES Reg. EU n° 1251/2013 of the commission 3/12/2013.

The process control is carried out by a PLC with a very simple programming logic and built-in Ethernet network interface. Through a specific app it is possible to control the system and its activities remotely from a PC or iOS or Android mobile devices.

The flow rate, pressures and temperature are measured and monitored to optimize the process, with self-regulation of the service fluids to guarantee the required oxygen and CO2 values in the wine at the exit.

The diagram graphically summarizes the operation of the ISIOX system. The passage of the wine in contact with the molecular sieve allows a gaseous exchange between the liquid and the process gas used: nitrogen, carbon dioxide or argon.